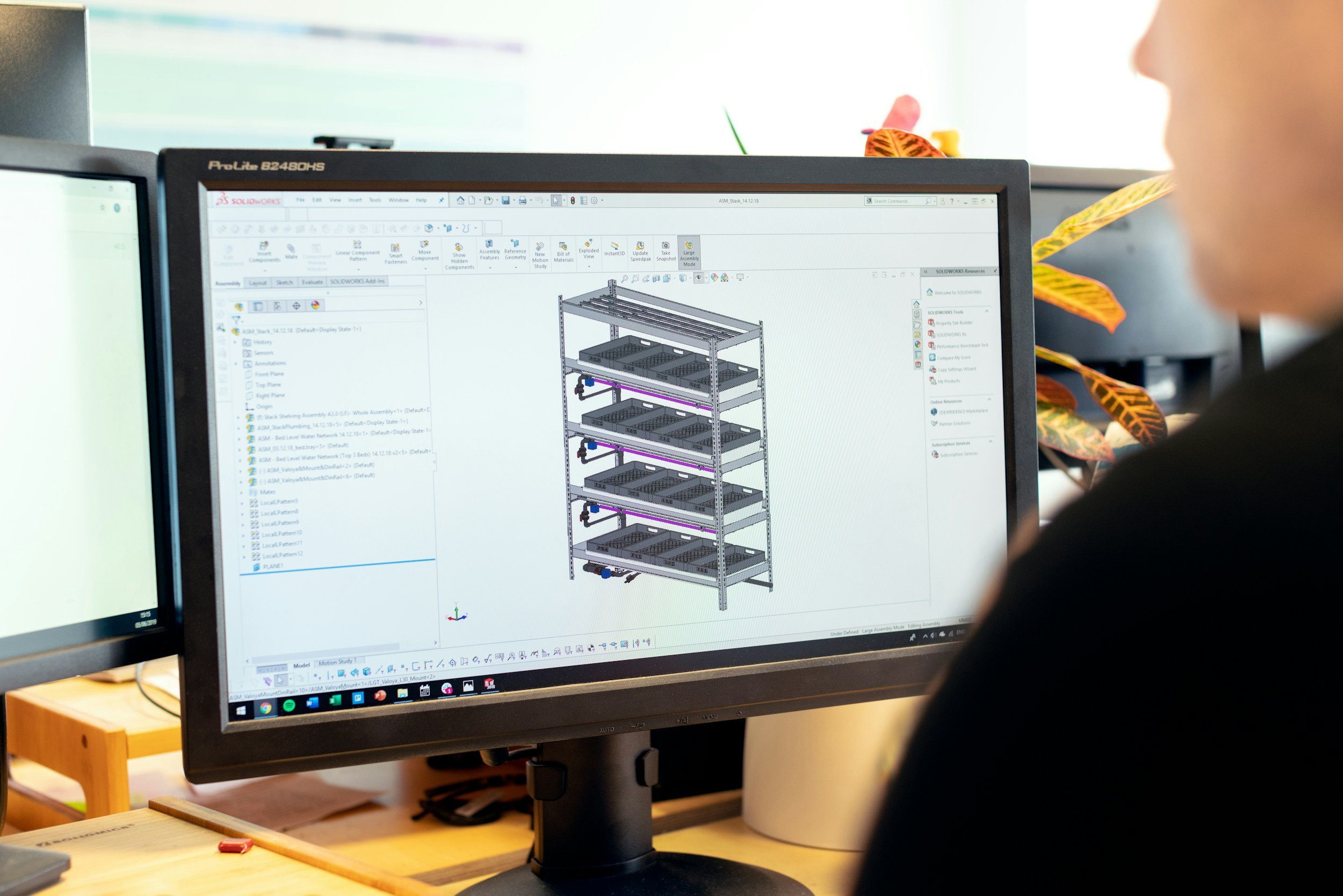

Prototyping & Design

Product Development

Made Easy

Whether you have existing 3D models, are seeking to update an existing part, or are still in the idea phase, Lindon Precision can take you from your starting point to functional prototypes quickly and without hassle. Explore materials, alternative designs, and more with our design team.

Why Lindon Precision

A Prototyping Partner

You Can Count On

Since opening our doors in 1975, we've made a habit of saying "yes" to manufacturing challenges. In addition to our state-of-the-art equipment, we boast some of the best programmers in the State of Utah, and we won't turn you away because of the complexity of your parts or designs. Have concerns about proprietary designs? No problem. We offer a seamless, worry-free experience from NDA to project delivery. Lindon Precision is a partner you can count on time and time again for all of your product development and prototyping needs.

-

Lindon Precision has offered machining and prototyping services to companies in Utah and throughout the West since 1975. Our programmers and engineers can get you from concept to working model without headache.

-

We recognize the importance of proprietary designs and protecting your intellectual property. With Lindon Precision, you can submit an NDA before beginning discussions with our team. Once we start, you can expect discretion and hassle-free prototyping and production from day one to delivery.

-

Maybe you've locked down a design for your components but are still exploring different materials or finishes. At Lindon Precision, we can help you develop parts from nearly any material, including plastics, nylon, composites, alloys, super alloys, and beyond.

Work hand-in-hand with our design team to pick your parts' proper form, look, and function. Once we complete initial prototypes, test internally and/or with your customers, and then work seamlessly with our team to develop a final product ready for market.

-

We've heavily invested in the latest machining and prototyping equipment, including CMM (coordinate measuring machines). We can reverse engineer existing parts and prototypes to develop full-scale 3D models that we can tweak, update, and prepare for market. Upon completion, we offer CMM reports with certificates of compliance.

-

Once prototypes are completed and you're ready to go to market, look no further; you can trust Lindon Precision for all of your mid-sized and large-scale production runs. Our fully loaded machine shop boasts 14 CNC machines and 24/7 production cycles, enabling us to get you from concept to prototype to market as quickly as possible.

How it Works

Start Prototyping in

3 Simple Steps

01

Reach Out

Get in touch with our team to discuss your prototyping or design needs. Send us 3D models, product sketches, or even just tell us about your idea. We offer free 30-minute consultations to help get you and your project rolling.

02

Quoting and Onboarding

After reviewing your project, we can provide you with a customized quote in as little as 24 hours. From here, we'll onboard your project, prepare 3D models for production, work with you to select materials, and prepare our equipment for the first articles.

03

Rapid Prototypes & Future Production

Next, we'll produce high-quality prototypes using your material of choice. We recognize the need for internal and customer testing, and we'll be here each step if you need to revise, test different materials, or reevaluate. Once your project is ready for market, our team will kick off a lightning-fast complete production cycle.

We’re Serious About IP

Protect Your IP

with Lindon Precision

We recognize the importance of trust in manufacturing. At Lindon Precision, you can rest easy knowing your proprietary designs and information are protected from quoting to delivery.

Your Prototyping Partner

With You From

Start to Finish

We love a design challenge! Wherever you’re at in the product development process, you can count on Lindon Precision to help you get across the finish line.